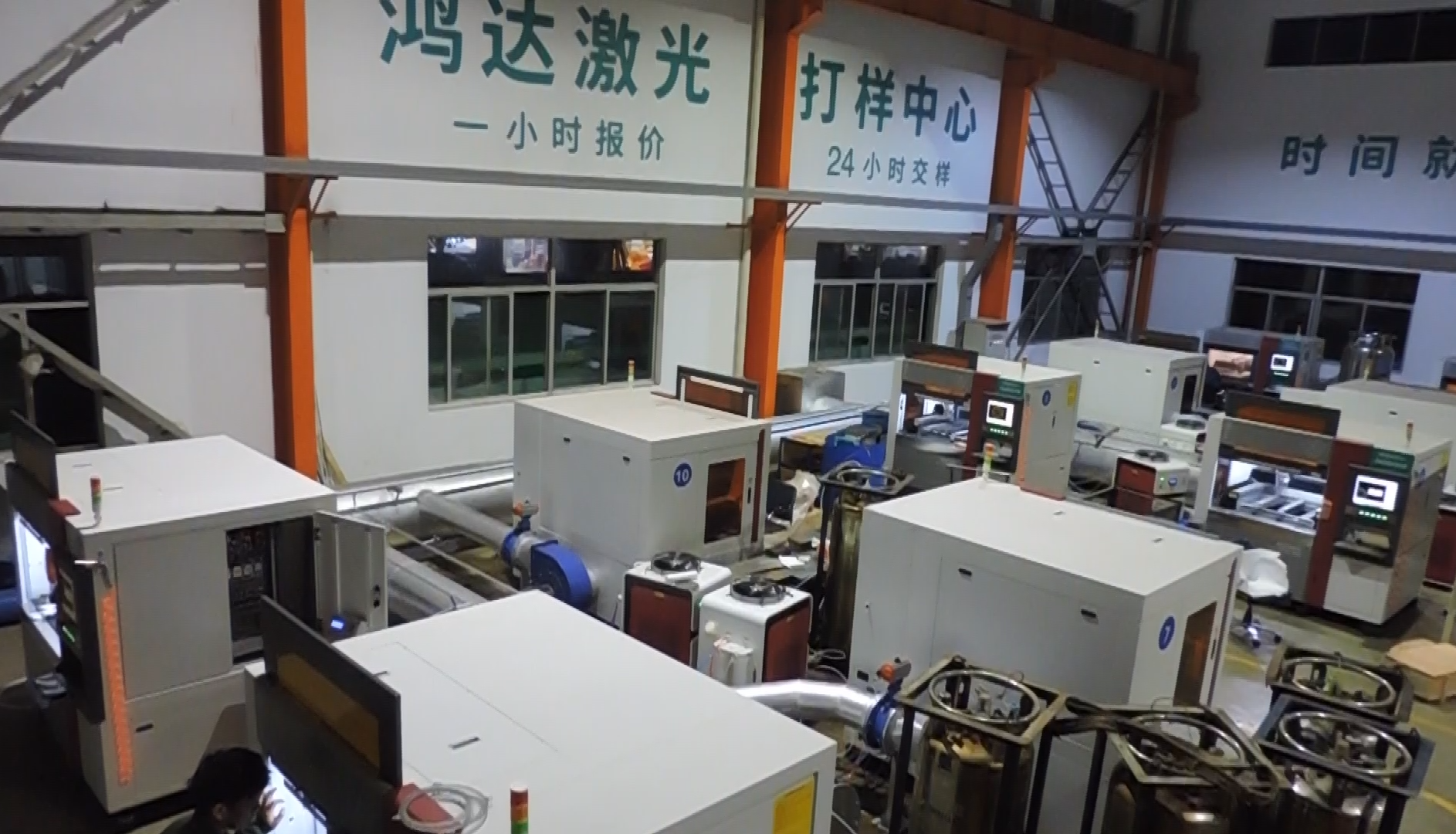

We hold several prestigious certifications, including ISO9001, FDA Certificate, and Intellectual Property Management Standardization. With over 70 certificates and patents covering laser cutting, marking, welding machines, and core photonic components, our extensive portfolio highlights our industry leadership and reliability in laser technology.